iBALLSCREW®

SMART BALLSCREW

SHUTON designs and manufactures precision ball screws for machine tools, injection moulding sectors, heavy load applications, automation solutions, etc..

The iBallscrew® combines sensors to monitor vibration and temperature. These data are processed locally by an Edge Computing system. The collection and analysis of data from sensors can help identify areas where performance can be improved and production processes optimised.

MONITORING PARAMETERS

THE KEY TO EFFICIENT PRODUCTION

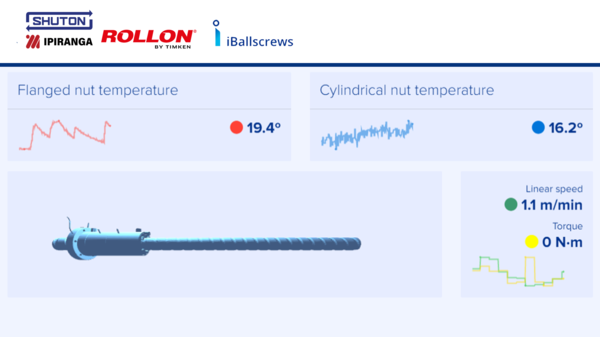

Temperature Monitoring

The ballscrew temperature monitoring can keep your machine in the best operating condition. Temperature is part of the fingerprint of the ballscrew, and its evolution and analysis is useful to control ballscrew’s health and performance. You can identify lubrication failures and optimize the lubrication strategy, adapting cycles and quantities to reduce the oil consumption and avoiding metal-metal contact amongst balls, rolling surfaces of screw and nuts that can accelerate the wear of the ballscrew.

Temperature monitoring improves the performance, maintenance, efficiency and safety of the production process.

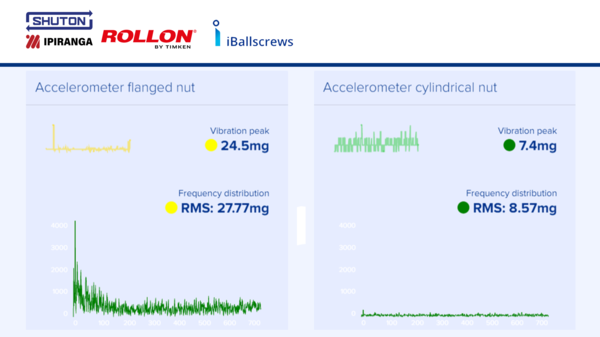

Vibration Monitoring

Ballscrew vibration continuous monitoring is an important tool that can help to keep your machine in the best operating condition. Vibration parameters are part of the fingerprint of the ballscrew, and its evolution and analysis can offer key information about the performance and status of the ballscrew.

Vibration monitoring can specifically be used to identify fatigue life issues in the rolling elements of the ballscrew, and also to measure the performance of the recirculation system. A correct analysis of the evolution can be used as a predictive maintenance indicator.

Extended Monitoring

By combining the temperature, the acceleration and other data from the machine, Nadella can support in monitoring the ball screw preload variation, hence the performance and efficiency of the machine.