AXNR Carriages – System Configuration

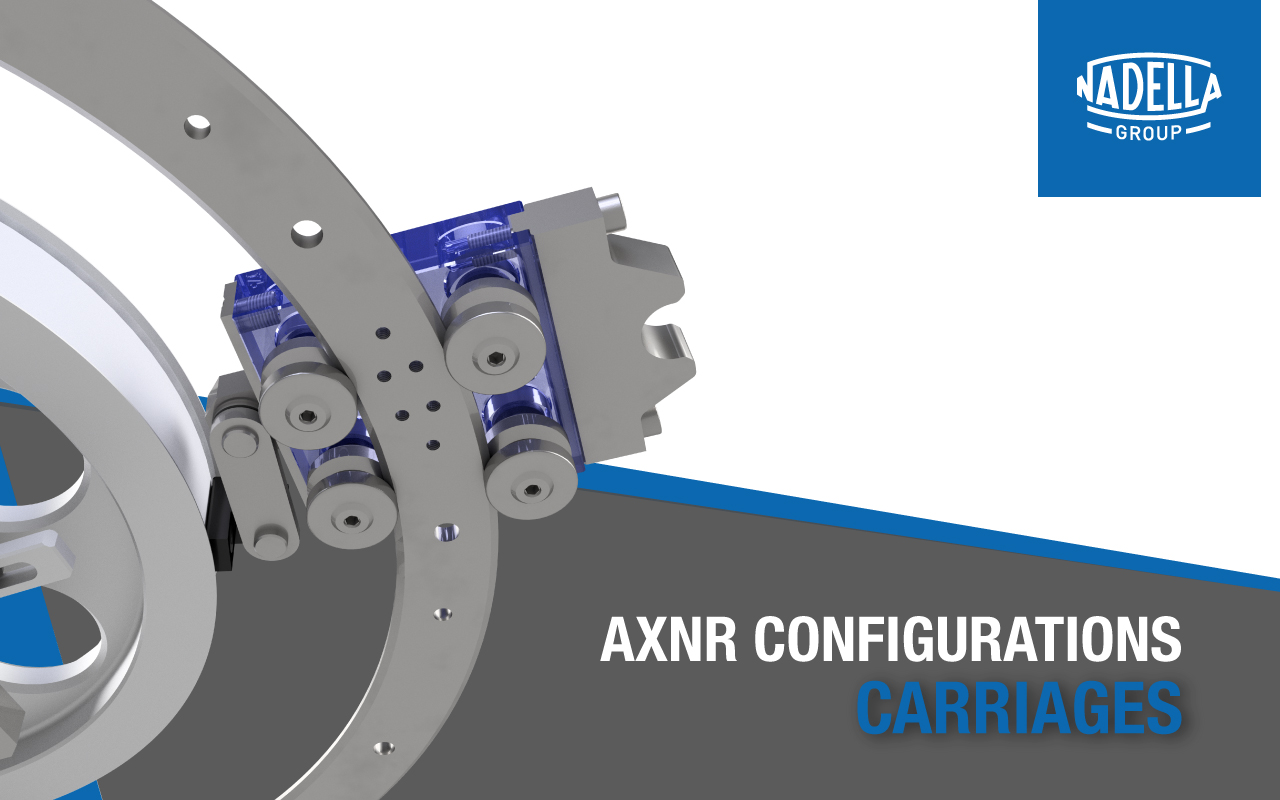

With carriages that are equipped with Nadella Guide Rollers a precise movement in the round and straight sections of the AXNR guide rail curcuit is allowed. The carriages support the load in both directions and are equipped with two concentric guide rollers ans two eccentric guide rollers. As the eccentric guide rollers are mounted on the inner side oft he curcuit they allow to set the preload.

In order to offer a ready-to-use product the normal preload is already set in the factory but on request a lower or higher preload can be required. The preload remains constant on the straight and on the round path, but during the transition, when two rollers are on the round rail and the other two are on the straight rail, the preload is lost and a small play between the rollers and the guide occurs.

Sainless steel guides and guide rollers are part of the Nadella standard range. Carriges in anticorrosion version can also be configured very easily. Most applications with anticorrosion requirement use stainless steel rollers in aluminium table and other steel components, as the cam for carriage location, protected by nickel plating. Fully stainless solution can be provided on request. The most common applications are for example: Test Lines, Bottling Lines, Battery Assembly Lines or High Speed Conveyors.

The body of the carriage is based on an anodized aluminium plate. Additional machining as reference holes can be easily done. If a speical carriage design is required to fit the needs of an application we are happy to help you. Just contact us or fill in the application form in our AXNR Brochure.