Circular system AXNR: application examples

The AXNR Circular Systemcombines the technologies of the Group and and thus consists of several parts like the Multi-Motion-Line circuits. It is a flexible and customisable complete system.

Its main selling points are:

- Reducing risks and project costs;

- Reducing labor costs;

- High load capacity;

- Steady and smooth movement;

- Compact space-saving system in the workshop;

- Easy and precise mounting.

Like the FSR guides from which it derives, the AXNR Circular System is suitable to several application fields, and provides an automatic unmanned solution on every process.

Here below some application examples:

- TEST LINE (link): this high efficiency space-saving test line is possible due to the combination of the AXNRO Circular System and AXN actuators, which provides an automatic unmanned solution on every process.

- BOTTLING LINE (link): it consists of both AXNRQ Circular System and AXN actuators for bottling, sealing, testing, marking and packaging processes. This line provides a space-saving automatic solution with high consistency.

- BATTERY ASSEMBLY LINE (link): Battery assembly line consists of a big radius AXNRO Circular System paired with articulated robots. The high quality of Nadella rollers guarantees remarkable load capacity and long service time.

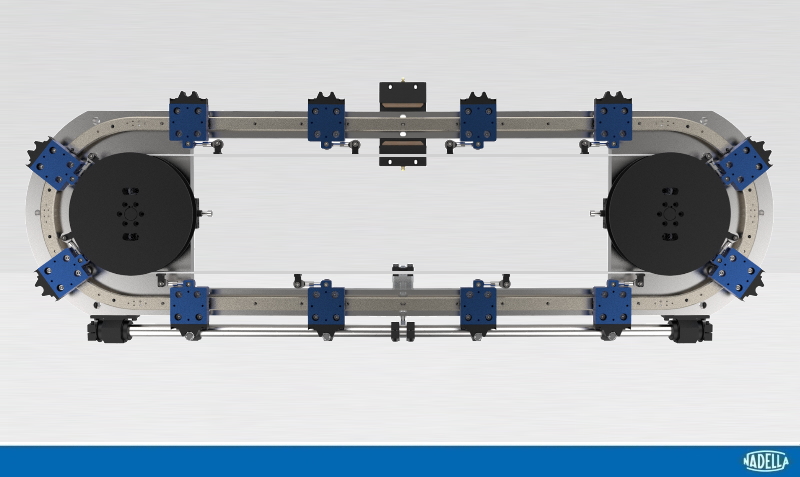

- HIGH SPEED CONVEYOR (link): Two AXNRO Circular Systems can be positioned parallel to each other to serve as a double row conveyor, developed specifically for high speed and precision positioning. All floating rollers on one side provide self alignment, which eases the parallelism tolerance of the two bases during mounting and results in a steady conveyor system.

For more further details on this system please consult the dedicated brochure, and if you have specific questions just send us a message through the CONTACTS section.