FWN guides for low to medium loads

The guides and runners of the FWN family can be used in all application sectors where a medium-low load capacity is required: from openings on machine tools to interlocking, handling, packaging and, thanks to a refined aesthetic, they can be left exposed. (also suitable for architecture).

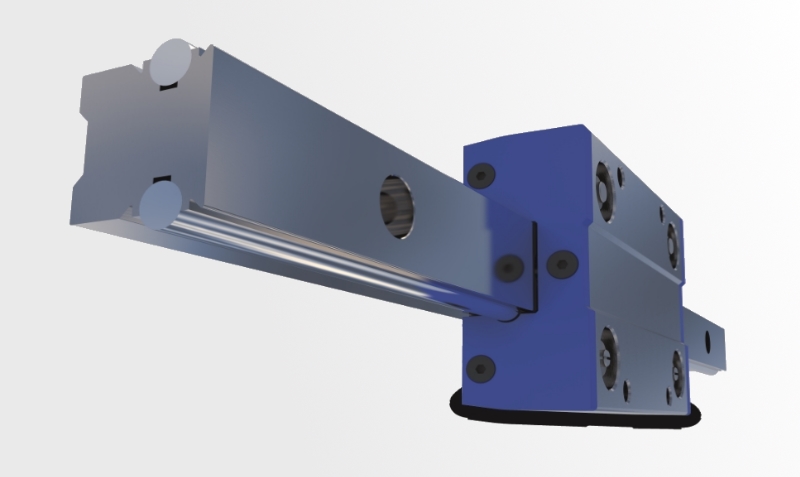

The guide, with the external sliding tracks, can be used as a monorail or in parallel with another guide. Furthermore, thanks to the combination of aluminum with stainless steel, this family of products can be successfully applied in the food and electro-medical sector.

Reliable, versatile and economical, FWN guides carry the Nadella hallmark.

Lightness and wear resistance

The light linear guides FWN (which join the light guides C, DC, FWS, FWH and LM) are made by combining two materials, namely aluminum alloy, which creates the basic structure, and hardened and ground Cf53 steel. (final surface hardness 60-66 HRC): two steel bars, which make up the sliding tracks of the guide, are firmly mounted on the aluminum extruded supporting profile; in this way the most favorable characteristics of the two materials and related processing technologies are combined: the lightness of the light alloy and the resistance to surface wear of the bars.

The aluminum profiles are made of Al6060 alloy, stabilized T5 (heat treatment that allows to confer hardness) and anodized.The FWN guide is currently available in two sizes, the FWN20, with a base width of 20 mm, and the FWN25, having a base width of 23 mm. To these two guides he adds the smaller FWN15.For the guide length and the drilling Nadella is very flexible: the customer can request the length necessary for its application and use the drilling presented in the catalog or request it from the drawing or buy the guide not perforated; the single guide section can reach a maximum length of 4,500 mm and for high strokes it is possible to approach several guide sections.

In addition to the freedom of choice with regard to length and drilling, Nadella adapts to customer needs: for use in oxidizing environments or in the presence of corrosive agents, the guides can be equipped with stainless steel bars (suffix NX), the material used is stainless steel UNI X90CrMoV18, the guides will be induction hardened with a surface hardness of 50 ÷ 56 HRC.

Interchangeable and compatible with recirculating ball guides

Both the geometric dimensions of the FWN guide and those of the TA / B4 roller shoes have been designed according to the DIN 645 standard and are therefore interchangeable and compatible with the recirculating ball guides available on the market.

The guide roller runners of the FWN family, unlike the ball recirculating runners, are more flexible, thanks to the absence of internal recirculation, in fact they tolerate better dirty and contaminated environments typical of the mechanical world and are decidedly more performing in all those low load and high speed applications.

In addition, the skids and guides are light, as they are made of aluminum, silent and sliding because they are on wheels and better tolerate misalignments which are prohibited due to the rigidity of the recirculating skids.