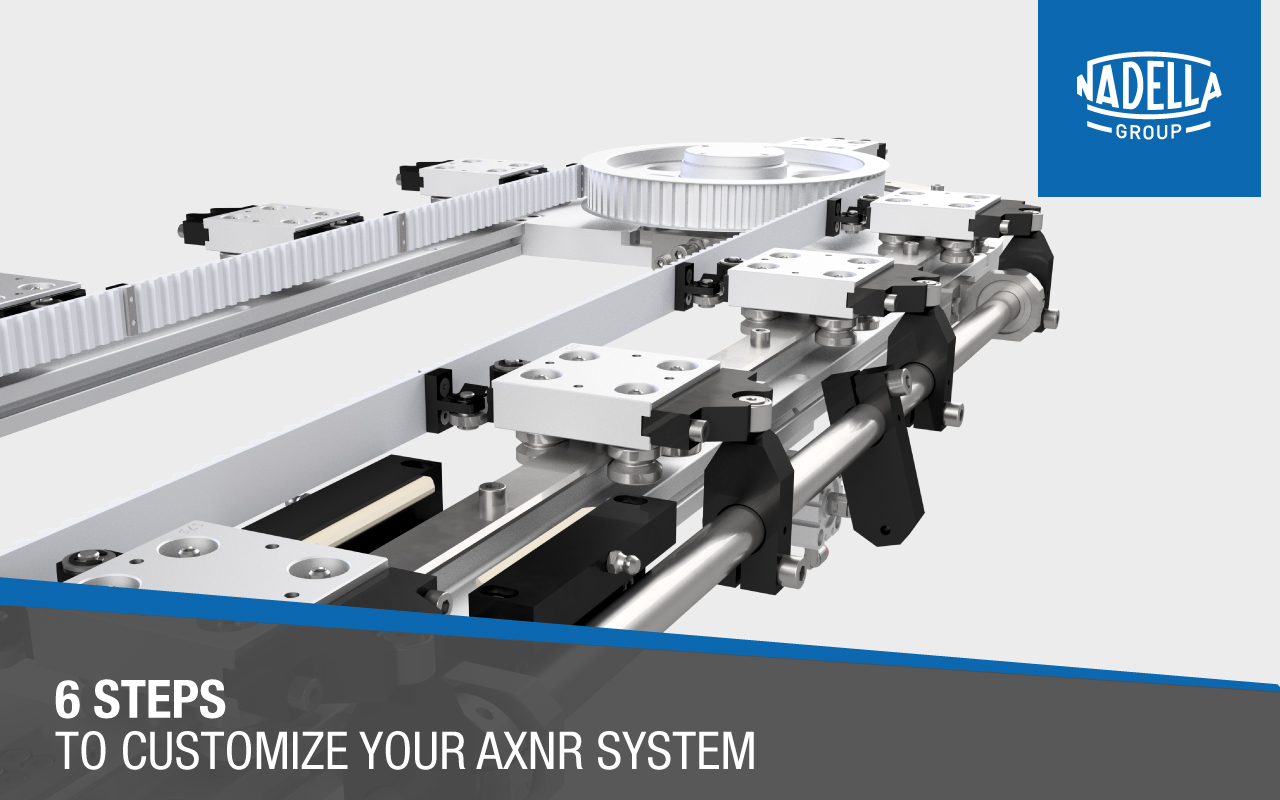

How to customize your AXNR system in 6 steps

With the Nadella AXNR sytem NADELLA provides a ready-to-use product that helps machine manufacturers to increase efficiency and achieve higher performances. Our circular module is a further developement of the FSR circular rails and it is based on the combination of diffenerent components to allow a better availability in short time and also product definition. With this system, modifications and special versions are possible to meet specific requirements of our customers.

Here are the 6 steps for the customization of your AXNR system:

1. Overall requirements of the application:

- what additional forces will be acting on the carriage?

- what is the weight and the dimension of the mass that needs to be handled?

- what will be the environment of the application – cleanness/ temperature?

- what will be the expected system life?

- how will the module be orientated in the space?

- what are the cycle details as acceleration, stroke, velocity and cycle time?

2. With the help of the tables in our catalogues you can calculate and choose the carriage dimension in accordance with load and load capability of the carriage. For more specific cases our Nadella service team is glad to advise you.

3. Choose between the configuration AXNO and AXNRQ and decide how many carriages you will need in you project.

4. Estimate the dimensions of the module. This can be done by calculating the belt length on which the dimensions depend on. Most of the times carriages are at constant pitch and the belt length is calculated as the number of carriages by the carriage distance – which has to be multiple of the belt pitch. Then the length of belt around pulleys has to be deducted from the belt length. As this result will be the length of the belt to the straight path, the value hast to be divided by 2.

If you choose the AXNRO configuration this value is a first estimate of the modle length X. For the AXNRQ configuration you will have to decide the desired width dimension Y and deduct it. Note that the X length is theoretical and the actual one will be increased a few mm to compensate the elongation of the belt during assembly. (This will be defined by Nadella during product definition phase).

5. Choose your options like the gearbox type, lubricator position or carriage position. For AXNRQ modules the corner for the location of the drive pulley has to be defined.

6. To simplify the offering process and the technical evaluation, please use ourAXNR application form. Our technical service will contact you as soon as possible after receiving the form.

Please download our catalogue to see more details and product tables. If you have any questions or need assistance feel free to contact us.