Linear Technology: Nadella keeps growing

The German-Italian linear technology manufacturer Nadella has again grown by two companies after several acquisitions in recent years.

A few key points:

- The linear technology manufacturer Nadella has a turnover of around 70 million Euros with around 300 employees

- Acquisition of the two Spanish companies Ipiranga and Shuton

- Plants in Italy, Germany China and Spain

Over 70 percent of Nadella's turnover is generated outside Italy and the company has been focusing on international growth in recent years. Now the company continues to grow through the acquisition of the Spanish companies Ipiranga and Shuton. The plants in Italy (Monza, Brianza and Bologna), Germany (Öhringen, Nufringen and Limburg) and China (ChangXing) are now joined by two further factories in Spain. Nadella already has sales offices in over 60 countries, including Italy, Germany, France, Great Britain, USA, India and China.

Linear technology extended by customized solutions for ball screws

The products of the two Spanish companies complete the range of the group: Husillos Ipiranga and Shuton are traditional companies specializing in the development and manufacture of high-precision ball screws. They serve the mechanical engineering, injection moulding and automation sectors.

Frank Scherer, Nadella GmbH director, explains: "Nadella has many years of experience in linear motion technology and has grown over the years through a consistent research and development strategy and major acquisitions: Husillos Ipiranga and Shuton are the fourth and fifth companies in six years, and they complement our offering as the best suppliers of ball screw solutions. This is an important step in our ongoing growth strategy and we are pleased to announce the acquisition in the year of our 90th anniversary".

The ball screws of the two newly acquired companies will expand Nadella's portfolio in the field of linear and rotary motion technology (linear guide components, telescopic guides, ball screw guides, needle bearings, rod ends and spherical plain bearings, linear modules).

Koldo Aranguren, CEO of IAZ Group, remains Managing Director of Husillos Ipiranga and Shuton. He explains: "I am confident that combining our ability to customize production with Nadella's commitment to meaningful innovation and international scale will bring sustainable and lasting growth, creating a positive impulse for our stakeholders".

Ipiranga brings new protection system for ball screws and a special surface treatment

The acquired companies bring interesting solutions with them. Ipiranga, for example, has developed a new system to better protect ball screws against environmental influences. The manufacturer of rolled and ground ball screws manufactures its products in numerous sizes and designs. The company can implement options such as an additional safety nut, heavy duty versions, rotation nuts, or a maximum length of up to 20 meters. The spindles are often used in applications with demanding conditions. These include the nuclear sector, aeronautical engineering or use in ports and airports.

The company also has a special surface treatment for the products: The alloy material of nickel and molybdenum in combination with surface treatment in the form of a chemical layer of manganese phosphates offers reliable protection against damp and salty environmental influences.

In order to resist dirt and at the same time improve oil tightness, Ipiranga has developed a special scraper that keeps dirt away, especially that which occurs during sawing, punching and grinding. The newly developed protective device not only effectively seals the ball screw nut, but also protects the lubricant.

Linear technology combined into automation solutions

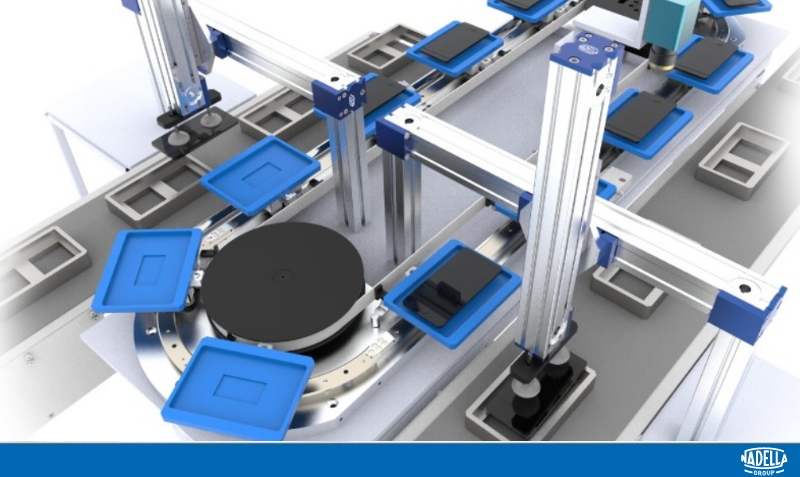

The growth and constant expansion of the product range offers the Nadella Group the opportunity to combine the technologies of the various products and thus to offer complete systems from a single source.

With the AXNR oval system, for example, Nadella offers a complete linear drive system with toothed belt drive as a flexible and adaptable complete solution. This complete system minimizes risks and project costs. The design and the smooth interaction of the components ensure, in addition to simple and precise installation, a high load capacity with continuous and trouble-free operation. It can also be integrated in a space-saving and compact way. The system is based on FSR guides.

Filling, sealing, testing, marking and packaging lines can be implemented in combination with AXN drives. Such lines can be integrated in a space-saving manner and are characterized by smooth operation. A battery assembly line also integrates articulated arm robots. The Nadella rollers offer a high load capacity and ensure long operating times.

A high speed conveyor system is realized with two AXNR oval systems, which are positioned parallel to each other. The double-row conveyor system was specially developed for high speeds and precise positioning. The floating rollers, which are self-aligning on one side, facilitate the parallelism tolerance of the two surfaces during assembly, resulting in a stable conveyor system.

--

Link to the original article published on DIGITAL ENGINEERING