ROLBLOC systems

The carriages based on ROLBLOC system are recommended for applications with heavy loads, high frequency of work and aggressive environment (dust, abrasive).

For the profiled guide rollers, the contact beween the rollers and the rail takes place on the ground raceways, which are inclined in respect of the rotation axis of the guide roller. Due to this inclination angle in the contact area there is a dragging proportional to the dimension of the contact area and to the value of the inclination angle.

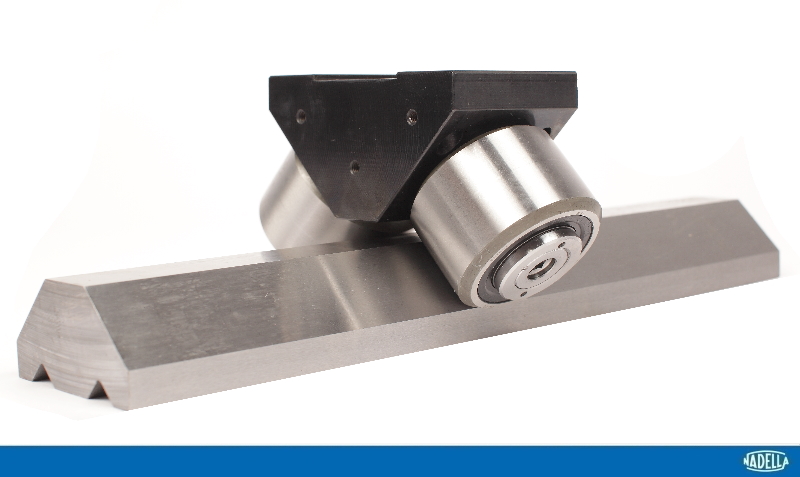

In the ROLBLOC system the rotation axes of the roller guides are parallel to the raceways of the rail, with the following pure rolling. The pure rolling reduces the superficial stress and the effects of the dust between the surfaces. ROLBLOC carriages BL2 ... and BL4 ... are composed by a body in burnished steel on which are mounted two or four roller guides equipped with tapered rollers (similar to flat roller guides type PK...C).

Rolbloc carriages BL2 ... DS have a special block profile with a profiled surface close at the rail GU...M or MT.

How does it work?

The space is set so that during normal operation there is no contact between the block and the rail and the carriage moves on its rollers. When the load goes over the normal value the deflection of the rollers reduces the space since there is direct contact between the rail and the block.

In this way the system is protected versus extremely and or uncontrolled loads. When the extra load is removed the system returns in its normal position thanks to the rollers’ elasticity.

Rolbloc in DS version is a simple and effective solution in the following applications:

• Systems that have to be blocked in a position. The blocking system, i.e. a hydraulic cylinder or a bolt used as tie beam, can push directly the carriage against the rail without component damage risk.

• Systems where high stiffness support is required in a static operation. When the block is pushed in contact with the rail the system stiffness increases and stability is given versus deformation and vibrations.

• Systems that have to stand shocks and extra load that could compromise the roller resistance. This allows to select the component size on the normal load during the operation and not on the pickforce.

These systems are therefore perfect for use in the heavy or steel industry, and in foundry machines, marble or iron rod processing, automatic warehouses and in general in all applications with kinematic thrust, such as in the case of manipulators.

For any further infos on our ROLBLOC linear systems, please see the section LINEAR GUIDES or just send us a message through the CONTATCS page.